|

Qingdao grandwill machinery manufacture co., Ltd.

|

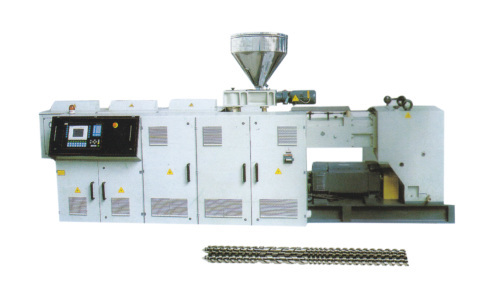

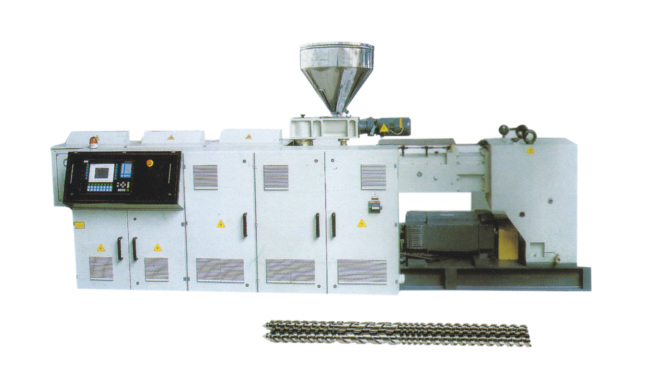

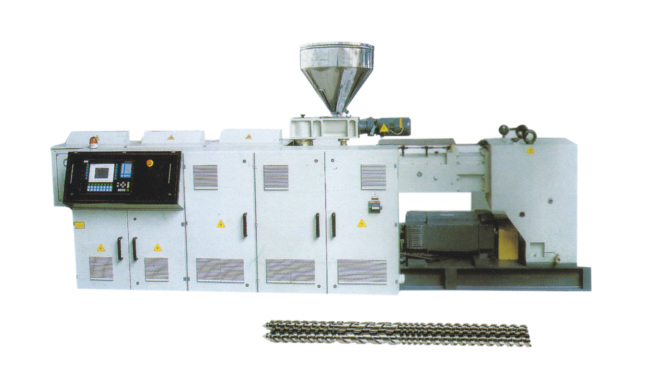

Parallel Screw Extruder

| Price: | 10000.0~40000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

With special high torque drive system, gear tooth and shaft are made of high intensity alloy steel, and are treated by the cemented and gear grinding.

Parallel Double Screw Extruder is a Gentle molding design, which guarantees the quality of the material. Very much dependable valid design theory guaranteed the dependable operation of extruding. With special high torque drive system, gear tooth and shaft are made of high intensity alloy steel, and are treated by the cemented and gear grinding. The fresh development screw may be applicable to the dispensation having great amount of padding, and guarantee the compacted ness and optimum material distribution; the parallel double Screw with core temperature regulation unit and well barrel cooling guaranteed the exact control of processing temperature for the materials. Matching with different standard of pipe die and auxiliary device, it is used to extrude different pipe, plate, profile and soft and rigid PVC granulation.

Our Parallel Double Screw Plastic Extruder is good in quality and competitive in price. We manufacture our own production line and supply OEM, ODM service according to your requirement.If you have any interest about our production line or any questions, please contact us either by calling +86 532 8523 5555.

The following specification shows more details about our extruder for you to choose.

TECHNICAL SPECIFICATION | |||||||

Model | Screw Diameter(mm) | Max. Screw Speed (rpm) | Effection Length(mm) | Driving Motor Power(kw) | Ceramic Heater | Max. Output | Overall Dimension |

Power (kw) | (kg/h) | (mm) | |||||

DSJSZ-51/105 | 51/105 | 1-30 | 1200 | 18.5 | 18 | 120 | 3620x1050x2157 |

DSJSZ-60/125 | 60/125 | 1-37 | 1200 | 37 | 24 | 180 | 3620x1050x2157 |

DSJSZ-65/132 | 65/132 | 1-34.7 | 1440 | 37 | 24 | 250 | 4235x1520x2450 |

DSJSZ-80/156 | 80/156 | 1-36.9 | 1800 | 55 | 36 | 400 | 4750x1550x2460 |

DSJSZ-92/188 | 92/188 | 1-32.9 | 2500 | 90 | 45 | 700 | 6725x1550x2814 |

Our Parallel Double Screw Plastic Extruder is good in quality and competitive in price. We manufacture our own production line and supply OEM, ODM service according to your requirement.If you have any interest about our production line or any questions, please contact us either by calling +86 532 8523 5555.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Parallel Twin Screw Extruder

Screw Extruder

Parallel Screw

Twin Screw Extruder

Single Screw Extruder

Double Screw Extruder

More>>